ME 101: “Visual Thinking” is one of the oldest courses on campus and is also a requirement for every mechanical engineering major. To make the workload more manageable for students this past year, the professors added more constraints to the students’ final projects.

Throughout this quarter-long course, students worked on three projects, each assigned one to two weeks before its due date.

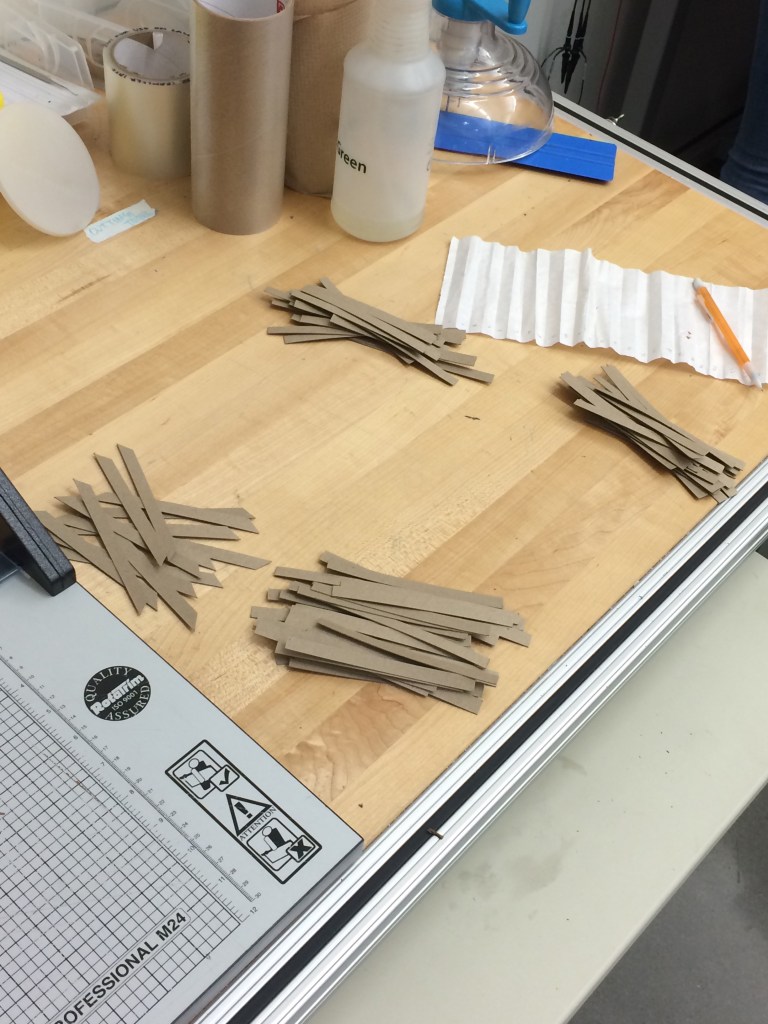

For the first project, groups of students built towers three to six feet tall entirely out of foam core to get a ping pong ball from one tower to another. The second involved building a pinball machine out of foam core and focused on both the mechanical designs and the aesthetics of the students’ projects.

The third and final project was completed alone as opposed to with a group, and it required students to identify a bug, or an error in a system, and then communicate a solution to that bug with a small prototype.

Marion Lepert ’17, who took the course in spring 2015, built a modified laser cutter machine with a redesigned interface for her final project after encountering problems with the original interface of the laser cutter. For Lepert, the projects were “stressful because there were a lot of parts that had to come together, and sometimes things don’t work out.”

Not only did the difficulty of the projects itself lead students like Lepert to feel stressed, but there was also a lack of convenient workspace for her and her group members in her dorm’s basement, which was their chosen and closest work environment.

“I can’t speak for other groups, but personally, we were kneeling on tables and using hot glue guns on couches,” Lepert said. “So there definitely was enough space for us to work, but the space wasn’t exactly tailored best to working on the projects, as it was more of a hangout area.”

To Lepert, creating the projects would have been “easier if [she and her group] didn’t have to work in the common workspaces.” She explained that by the end of their project, many of her groupmates could not even find their X-ACTO knife blades among the many ping pong tables and couches in the Crothers Hall basement.

Lepert believed that if they were working in more convenient spaces such as the Product Realization Lab (PRL), “[they] would probably be able to leave a lot of materials behind.” The PRL, a commodious lab room filled with specialized tools and machines, however, does not give open access to students throughout the nights. Its latest shift is from 7 p.m. to 11 p.m.

Yet mechanical engineering lecturer Brett Newman said that the PRL is not the right place for ME101 students to work. While the space is a great resource for several classes, the machines in-room are not suitable for the projects that the students do in ME101.

“It may be very well true that there isn’t enough space to work, but I’m not sure that the PRL is the place to do that,” Newman said. “None of the tools in PRL are the ones we would use in class. Those are for dealing with metal and plastic, [whereas] we use foam core and hot glue guns.”

The professors, aware that most students have had difficulties with workspaces as well as the transportation of materials, arranged the students into groups based on where they live for the projects.

In addition, according to lecturer and lead ME101 instructor Patrick Fenton, the professors this year decided to make the projects more doable for the students cost-wise and space-wise.

“We didn’t want our students to pull too many all-nighters like many have done so in the past, so in some of the projects, we saw that we could produce the same results by bringing the dimensions down a bit,” Fenton said. “So if a student had to work on the project in the bedroom, even though it is not ideal, it can still be done.”

Although there were still a few difficulties concerning the lack of convenient space for Lepert and her group, Lepert said that she was still able to successfully get the projects done.

“[The experience] wasn’t really catastrophic enough to bring up our concerns to the ME department; we were still able to complete our projects,” Lepert said. “We made do with what we already had, but it would’ve been more convenient to work at a better workspace.”

Antoine Screve ’16, who took the course during his sophomore year, however, was one of the few students who was able to use the Stanford Volkswagen Automotive Innovation Lab (VAIL), since one of his group members was part of Stanford Solar Car Project (SSCP).

“I think it could be a solution to have more extracurricular rooms like [VAIL] open for the ME101 students,” Screve said. “The experience wasn’t very stressful for me because I was able to work in a better workspace, whereas others might have not.”

Fenton, however, believes that the lack of a convenient workspace better prepares the ME101 students for the future.

“Having an entire ME101 workspace would be more of a desire than a need,” Fenton said. “[But] it’s not always going to be the case that you have enough desired space for your projects in the future, so this does prepare students in the long run.”

Contact Eileen Toh at eileen.toh ‘at’ saratogafalcon.org.