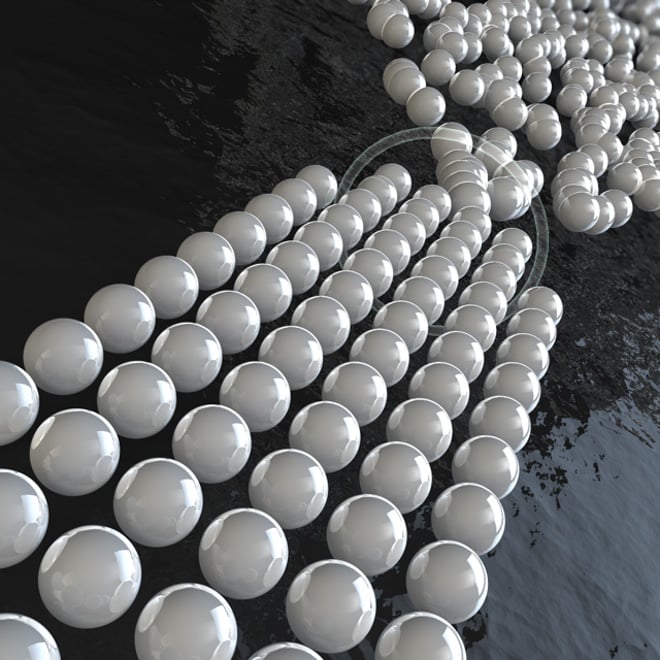

Researchers at Stanford’s Tang Lab recently released a paper investigating the spontaneous emergence of order in oil-filmed water droplets squeezed through a funnel. This finding has many potential applications, including modeling microscopic crystals and developing more efficient sample testing methods.

Tang Lab first noticed the spontaneous order among water oil droplets when they looked at the research project of Ryan Swodoba ’14, one of their undergraduate lab members. Swodoba started working in Tang Lab the summer after his sophomore year as a material science and engineering major. He was working with microscopic droplets of water, around 50 picoliters in volume, surrounded by a thin layer of oil.

Tang Lab studies the potential for the droplets to be used as mini test tubes to hold different samples. Swodoba was trying to figure out how quickly he could flow these droplets through a funnel without them breaking apart.

“It was really the groundwork [Swodoba] built up that led to later discovery that was picked up by Ya, who joined our lab a little later,” said Sindy Tang, assistant professor in the department of mechanical engineering.

Several years later, Ya Gai, a Ph.D. student in aerospace, aeronautical and astronautical engineering, re-visited the strange behavior of these droplets when they were extruded from the funnel at slower speeds.

“The droplets move like batches,” Gaid said. “And the location and the timing of this … seems to be very organized. We expect them to be stochastic and unpredictable, but it appears to us they are very ordered.”

In order to try to understand why the droplets were acting this way, Tang Lab collaborated with Wei Cai, an associate professor of mechanical engineering. Cai looked at the droplets from a solid mechanics view and discovered that they might be a good model for understanding the dynamics of microscopic crystals.

“It will be a model for a solid crystal, and what happens when we try to squeeze these solid crystals through this extrusion process going from a wider [space] into something that’s like a nanowire,” Tang said. “We realized there’s actually a very easy analogy between the experimental results we found and the solid mechanics that have been know for many years.”

Another possible application of this research is to improve the use of water oil droplets as a method for testing many samples as efficiently as possible. According to Tang, the benefit of traditional 96-well plates is that the position of the well will tell you what reaction is inside. Conversely, one of the current disadvantages of the water droplet sampling technique is the inability to predict the exact order that the samples will run.

“With these drops … once you make them, they flow around and mix, so you lose track of which drop contains what,” Tang said. “[But] with this order we can possibly predict where the drops will go and basically allow us to retrieve the spatial encoding that we have lost with this droplet system.”

Contact Aulden Foltz at afoltz ‘at’ stanford.edu.